Showroom

This range of spin finishes emulsions is used for nylon/PP or polyester yarns. Made by using advanced manufacturing process, this array of emulsion based substances show consistent performance. Free from toxic content, these emulsions have standard shelf life.

Textile Lubricants are well known for their excellent anti static attributes. Formulated under controlled environment, this array of lubricants can be availed in different composition based choices. This product range is cost effective.

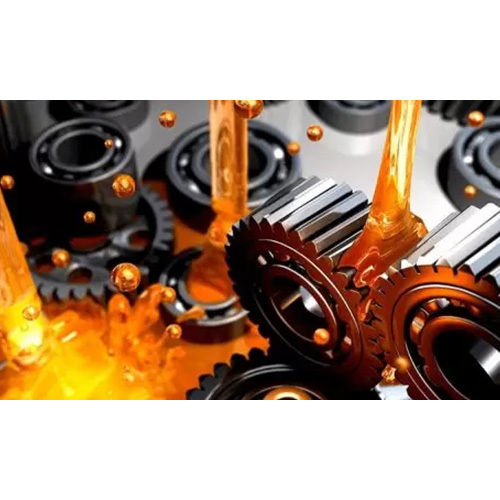

Industrial and Automotive Lubricants are well known for their excellent wear protection capacity, standard viscosity level and ability to perform well at high pressure prone working condition. Offered oils help to extend service life of engines.

Rubber Process Oils and Plasticizers are used as the basic ingredients for vulcanization process. Free from unpleasant smell, these products can be availed in different formulation based choices. We offer this product range at reasonable rate.

This array of Industrial Paints and Coatings is applied on metallic surface to avoid wear, abrasion and corrosion formation. These are basically applied on various fixtures, pipelines and machine components to extend their functional life.